Services

The Section on Instrumentation Core Facility provides engineers and technicians to fabricate custom electronic, mechanical, and electromechanical devices and instruments for a full spectrum of biomedical applications. These services include (but are not limited to):

Design

Fabrication

On-Site Integration

Design

Our engineering team develops custom electronic, mechanical, and electromechanical systems for neuroimaging and behavioral testing. We support a wide range of biomedical applications by providing expertise in mechanical, electrical, and software engineering, including:

Mechanical

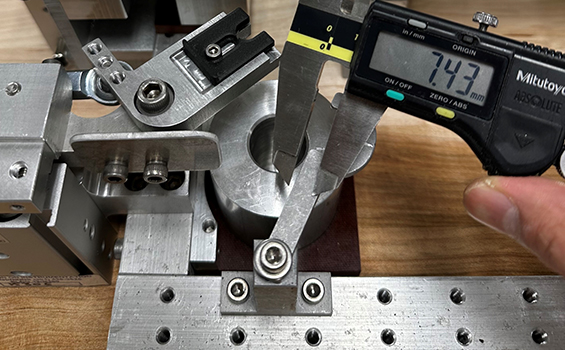

- Advanced CAD/CAM design

- Custom experimental fixture design

- Design for MRI imaging compatibility

Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) streamline design and manufacturing processes for optimized performance. Custom experiment fixture design addresses specific experimental requirements. Design for magnetic resonance imaging (MRI) addresses the unique material and design considerations to ensure compatibility with these systems.

Electrical

- Mixed signal circuit design

- Printed circuit board design

- Motion control

- Reverse engineering

- Electrical noise reduction

Mixed-signal circuit design integrates analog and digital components for high-performance systems. Printed circuit board design ensures optimized layouts that enhance reliability and minimize noise. Motion control solutions include motor control systems with motion sensors for precise automation. Reverse engineering enables hardware analysis, modification, and enhancement. Electrical noise reduction techniques, including shielding, filtering, and grounding, improve system stability. Designs focus on efficiency, precision, and performance.

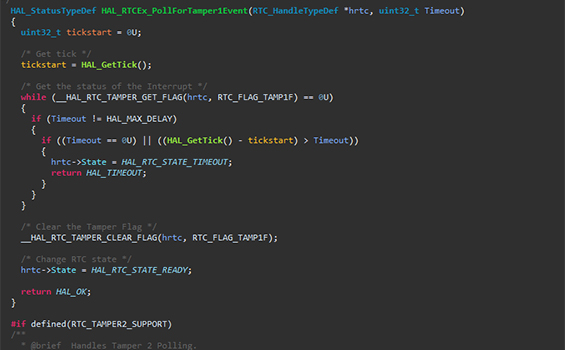

Software

- Human and Machine Interface

- Automation

- Data logger

- LabVIEW

- Embedded programming

Human-Machine Interface (HMI) development for intuitive user interaction. Automation solutions for streamlined processes and improved efficiency. Data logger implementation for real-time data collection and analysis. LabVIEW programming for test, measurement, and automation applications. Embedded software development for STM32 and Arduino platforms, enabling precise control and integration.

Fabrication

Our fabrication team specializes in high-precision manufacturing, ensuring that each device meets safety, durability, and functionality requirements. From concept to production, we offer:

Machining

- Precision cutting and shaping

- Power cutting

- Handling various materials

- Welding

Precision cutting and shaping using milling machines, computer numerical control (CNC) and various other machines. Power cutting with water jet technology cuts through almost any material. Expertise in handling various materials, including plastics, fiber, and metal sheets, allows for versatile manufacturing solutions. Welding services provide strong, durable, and structurally sound assemblies for a wide range of applications.

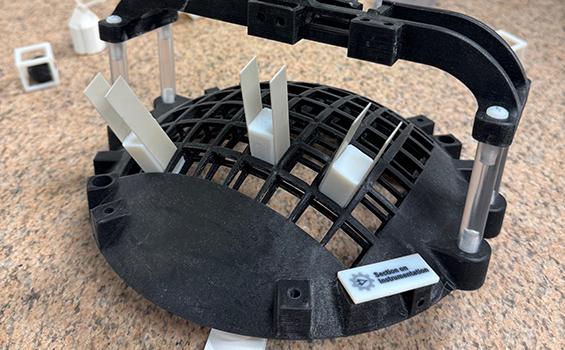

3D Printing

- Precision custom parts

- In-house post-processing

- Printing Capabilities: FDM, SLA, MJM and DLP

Precision custom parts with complex geometries meet specialized design requirements. In-house post-processing enhances durability, surface finish, and performance. Fused deposition modeling (FDM) produces strong, cost-effective prototypes and functional components. Stereolithography (SLA) delivers high-detail parts with smooth surfaces. MultiJet modeling (MJM) / PolyJet enables multi-material and high-resolution printing. Digital light processing (DLP) provides fast, precise, and high-quality resin-based prints.

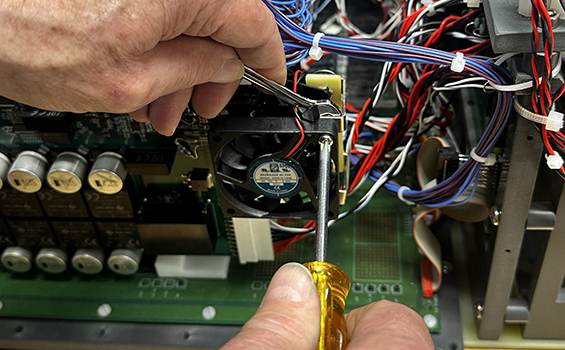

Assembly

- Wiring harness fabrication

- Printed Circuit Board Assembly (PCBA)

- Enclosure design for housing

Wiring harness fabrication ensures reliable connectivity and signal integrity. Printed circuit board assembly (PCBA) integrates electronic components for optimal functionality. Enclosure design provides durable housing for electronics. Expertise in through-hole and surface-mount soldering ensures secure and high-quality connections.

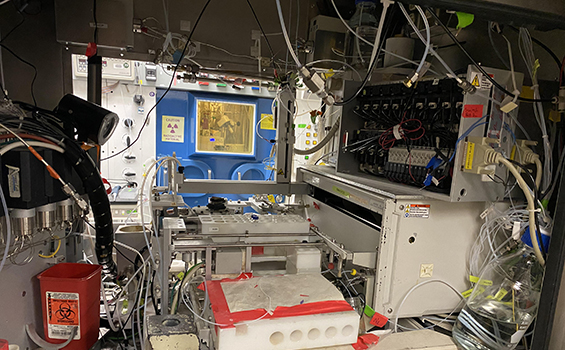

On-Site Integration

The NIMH Section on Instrumentation stands out in its ability to provide onsite to NIH researchers in developing and maintaining specialized research tools, including:

Setup & Installation

- Custom fixture design

- EMI shielding solutions

- Integration with existing or new equipment

Custom fixture design ensures compatibility with specific environments and operational requirements. Electromagnetic interference (EMI) shielding solutions minimize electromagnetic interference and improve system reliability. Integration with existing or new equipment enables seamless functionality and enhances overall performance.

Custom Modification

- Integration of unique features

- Performance optimization

- Hardware and upgrades

- Reverse engineering and redesign

Integration of unique features provides functionality that cannot be purchased off the shelf. Performance optimization enhances speed, efficiency, and reliability. Hardware and firmware upgrades improve functionality and ensure compatibility with modern systems. Reverse engineering and redesign modernize legacy systems for better usability and performance.

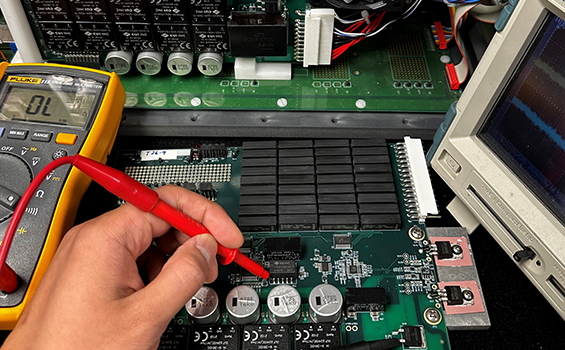

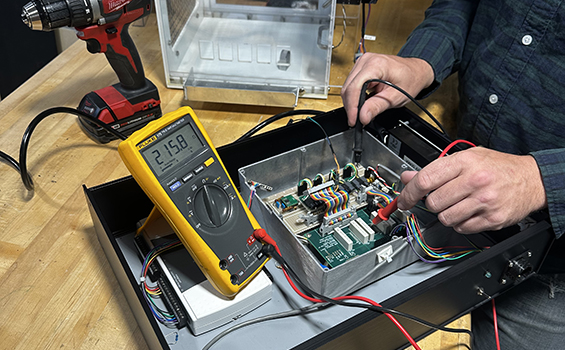

Diagnostics

- Noise measurement and analysis

- Component replacement

- Diagnosis of non-serviceable equipment

- Fault detection and troubleshooting

Noise measurement and analysis identifies and reduces electrical interference. Component replacement restores functionality and extends device lifespan. Diagnosis of obsolete or non-serviceable equipment assesses repair or replacement options. Fault detection and troubleshooting pinpoint hardware and software issues.